PROBLEM STATEMENT

Manufacturing data was scattered, visibility was limited, and decision-making was reactive. A unified, scalable platform was needed to bring real-time insight, trust, and foresight to global pharmaceutical operations.

Role

UI/UX Designer, Product Strategy

Time

~18 months

Team

20 people

Industry

LifeScience, B2B

Quick Summary

⭐️Context

Predictive Insights Center (PIC) is a data intelligence platform designed for Takeda Pharmaceuticals to bring foresight and clarity to global drug manufacturing. The existing ecosystem was fragmented, with siloed teams and limited visibility slowing down critical decision-making. PIC aimed to unify operations, streamline workflows, and enable teams to anticipate challenges before they occurred.

✅SOLUTION

The platform was built from the ground up as a scalable enterprise system with live batch traceability, predictive analytics, and role-based dashboards tailored for QA, production, and leadership teams. Supported by a robust design system and data governance model, PIC delivered a consistent, trustworthy interface that connected 30+ manufacturing sites and empowered teams to act proactively.

🎯RESULT

PIC transformed reactive monitoring into proactive insight. Process visibility improved by 55%, user adoption grew by 32%, and lead time dropped by 11%. Beyond metrics, the platform fostered a shared sense of clarity and confidence across global teams — setting a new benchmark for digital transformation in pharmaceutical manufacturing.

Context

Pharmaceutical manufacturing is deeply data-driven — but also fragmented. Teams across QA, logistics, and manufacturing used disconnected systems, delaying insights and creating risk. PIC was born to unify it all into one connected platform that could trace, predict, and prevent — before things go wrong.

Over 18 months, I helped turn that idea into a global platform that now connects 30+ sites, improves lead time and reliability, and enables proactive, data-driven decisions across manufacturing and supply.

My role

🎨

UX & Product Design

Led research, design, prototyping, and Information Architecture

🤝

Collaboration

Worked with cross-functional teams

📊

Research

Heuristic evaluation, CMI testing, user insights.

My Responsibilities

As the UX Designer + Product Strategist, I led the design from the ground up — shaping both the product direction and the end-to-end user experience.

My contributions included:

Conducted research across global teams and user roles

Designing the end-to-end UX/UI and data visualizations

Facilitated cross-team collaboration between design, data, and dev

Defined personas, workflows, and product architecture

Created the scalable design system and governance model

Ensured design decisions aligned with business outcomes

100+

Screens designed

12+

User flow defined

1

Unified Design System

Context & Challenge

Pharma manufacturing involves thousands of variables — batches, tests, shipments, and compliance checks — each handled by different teams and tools.

The organization wanted to unify everything under a single, scalable platform capable of:

Real-time batch traceability

Role-based dashboards

Predictive analytics and anomaly detection

Problem summary:

Fragmented data systems

Low visibility across supply chain

Inconsistent experience for each role

Delayed investigations and rework

The goal: create a unified digital platform that allows teams to monitor live batches, predict issues, and make informed decisions in real-time.

Discovery

We began with deep research to understand how people across manufacturing, QA, logistics, and planning were actually working — and where friction lived.

What we did

Field observations and shadowing sessions

50+ interviews across regions

Data audits of existing traceability tools

What we learned

User Quote

“I have to open three different systems just to confirm if a batch passed testing.” — QA user

Every role (QA, operator, planner) needed different data depth.

The biggest gap wasn’t data visibility, it was data clarity and confidence.

People didn’t trust their data, even when it was “available.”

Discovery Process

Miro Board Journey & Notes

We used notes made by PO and combined them with the ones that we made to make sure out data and flows was understood thoroughly.

User Workshop Miro Board

A detailed and in-depth miro board that showcases the details of the initial interactions and workshop conducted with the users.

User Activity Identifying Frustrations

In the workshop that was conducted, the users were asked to jot down their frustrations in the current system.

Framing the Problem

We reframed our core question:

How might we empower every stakeholder — from operator to executive — to trust, trace, and act on live manufacturing data with confidence?

Strategic Goals

Build one system of truth across operations.

Create role-specific experiences instead of a one-size-fits-all dashboard.

Enable predictive insights to shift from reactive to proactive.

Establish design governance for global scalability.

Product Planning

We split the platform journey into four iterative releases — each tackling complexity in layers.

Phase

Focus

Users

1

Live Batch Traceability (MVP)

Operators & QA

2

Inter-site Logistic & Planning

Planners

3

Predictive Analytics & Forecasting

Analytics & Leadership

4

Customisation

All roles

This ensured we could ship measurable outcomes early while designing for long-term scalability.

User Persona

From 50+ interviews across global sites, we identified key user groups. Each had distinct goals, data needs, and interaction patterns — making role-based experiences critical to our design strategy.

These personas shaped information architecture, dashboard structure, and feature prioritization.

Instead of building a “one-size-fits-all” interface, we designed role-based experiences, ensuring each user group saw the right data, at the right time, in the right way.

Information Architecture

Built a modular IA that scales with user roles. Tested labels and grouping with card sorting exercises.

Outcome: Clear, role-optimized navigation across 10+ user types.

Workflows

I mapped end-to-end flows for:

Monitoring live shipments

Investigating a failed batch

Comparing site performance

This helped identify unnecessary clicks, unclear hand-offs, and opportunities to automate manual steps.

Wireframing

Visual Design

Once the flows were validated, I moved into high-fidelity design focused on clarity and usability.

Focused on “clarity over decoration,” modular dashboards, trace lineage view.

Design System

To make the product scalable and consistent, I built the PIC Design System from scratch.

Included

Tokenized color system and spacing scales

Reusable tables, modals, cards, graphs

Accessibility standards baked in

Documentation for designers and engineers

This design system later became the foundation for multiple enterprise products across the organization.

Testing & Validation

We conducted multiple validation rounds with real users throughout different project phases to ensure that the experience was both usable and impactful in the real manufacturing environment.

Usability Tests with QA Teams

Simulated real Quality assurance workflows.

Found key friction points and simplified complex flows.

Adjusted technical terms for better clarity.

Prototype Navigation Tests with Operators

Tested low & high-fidelity prototypes on the floor

Merged scattered data views into a single dashboard.

Refined color, hierarchy,& iconography

Feedback Sessions Post-Deployment

Collected live feedback from 30+ site users

Refined predictive alerts and visual priorities

Continuous updates based on behavior data

Impact of Testing

11%

decrease in lead time

55%

increase in process visibility

32%

growth in user adoption

6%

decrease in human error

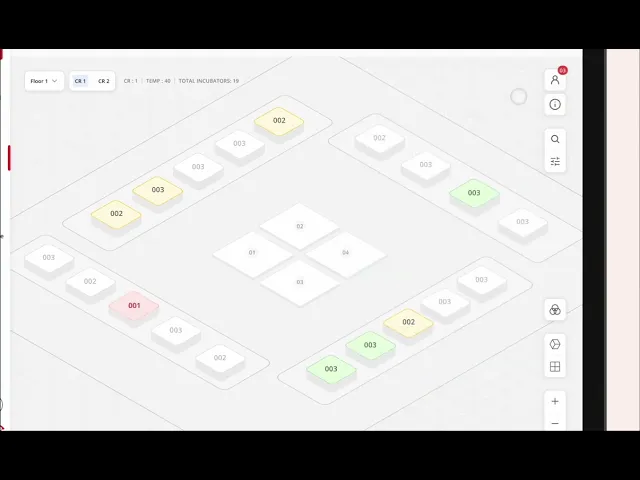

Solution

Predictive Insight Center (PIC) brought together traceability, performance, and predictive analytics in one intuitive platform.

Core Capabilities

Live Batch Traceability: Every batch’s journey visualized in real time.

Role-Based Dashboards: Custom views for operators, QA, and leadership.

Exception Alerts: Automated prioritization for high-risk batches.

Predictive Recommendations: Early warnings to prevent failures.

Scalable Design System: Unified experience across 30+ sites.

Recognition

Deloitte Outstanding Market Contribution Award

for project impact and innovation

Outstanding Performance Award

for leadership in UX and design strategy

Outcomes & Learnings

1

Design systems are business multipliers

Investing in consistency early enabled exponential scalability later

2

Data-dense doesn’t mean confusing

Clarity, hierarchy, and visual rhythm can turn complexity into confidence

3

Deep collaboration drives enterprise success

Working closely with devs, analysts, and QA helped ensure adoption and technical feasibility

4

Proactive design starts with empathy

Understanding users’ daily frustrations turned into solutions that truly saved time and reduced risk

Reflection

This project changed how I view enterprise design.

It taught me that great UX in data products isn’t about making dashboards look pretty — it’s about giving people trust and foresight in moments that matter.

From a blank page to a globally scaled product, PIC was proof that when design meets empathy and strategy, it can truly reshape how an entire industry operates.

Detailed Figma prototypes and interaction flows are available upon request.

Request Access

When insight is clear, decisions move confidently forward.

Predictive Insights Center — Takeda

To view the case study, please open this portfolio on desktop

Predictive Insights Center — Takeda

To view the case study, please open this portfolio on desktop